Fiberglass FRP/GRP elbow

Fiberglass FRP/GRP elbow

FRP elbows are made of glass fiber reinforced plastic, which is based on the resin mixed liquor, glass fiber and its fabric as reinforcing material, and is laid on the mould coated with mold release agent by hand.

The fiberglass reinforced plastic elbow has beautiful appearance and easy to install. Simple structure, smooth inner wall, not easy about aging, light weight and many specifications. Easy to transport, short construction cycle, low construction cost, convenient installation and maintenance.

Elbows are important fixtures used to change the direction of electrical and utility piping systems. Fiberglass Elbows revolutionized the industry as a cost-effective alternative to rigid steel/PVC elbows.

Fiberglass elbows are the first choice for applications requiring increased durability, corrosion resistance, or reduced weight. Fiberglass construction withstands friction better than other common materials and prevents burn-through when the cable is pulled.

Advantages of Fiberglass Elbows

Burn through

Epoxy fiberglass elbows and elbows are highly resistant to cavitation or puncture due to rope pull.

Low coefficient of friction

Lower coefficient of friction than steel and much lower than PVC. Lower friction makes it easier for cables to thread through, saving labor.

Light

Much lighter than steel and lighter than PVC SCH.40

Preservative

Epoxy fiberglass is unaffected by water and will not degrade in corrosive environments.

Cost-effectiveness

Lower installation costs compared to steel elbows.

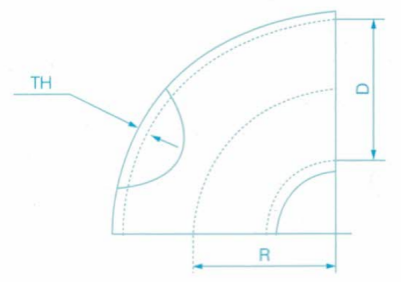

FRP pipe elbow/GRP elbow specification:

1. Diameter: DN10-DN5000 (mm)

2. Pressure rating: 0.1MPa-2.5MPa/PN1-PN25

3. Hardness level: SN1250-SN10000 (N / m²)

4. Other pressure levels, stiffness grade, non-standard length of the pipe can be custom processing and we can also do.

D | R | 0.6MPa | 1.0MPa | 1.6MPa | |||

TH | L | TH | L | TH | L | ||

10 | 15 | 5.5 | 115 | 5.5 | 115 | 5.5 | 115 |

15 | 22.5 | 5.5 | 122.5 | 5.5 | 122.5 | 5.5 | 122.5 |

20 | 30 | 5.5 | 130 | 5.5 | 130 | 5.5 | 130 |

25 | 37.5 | 5.5 | 137.5 | 5.5 | 137.5 | 5.5 | 137.5 |

32 | 48 | 5.5 | 148 | 5.5 | 148 | 5.5 | 148 |

40 | 60 | 5.5 | 160 | 5.5 | 160 | 5.5 | 160 |

50 | 75 | 5.5 | 175 | 5.5 | 175 | 5.5 | 225 |

65 | 97.5 | 5.5 | 197.5 | 5.5 | 247.5 | 5.5 | 257.5 |

80 | 120 | 5.5 | 270 | 5.5 | 280 | 5.5 | 320 |

100 | 150 | 5.5 | 300 | 5.5 | 330 | 9.4 | 400 |

125 | 187.5 | 5.5 | 387.5 | 5.5 | 417.5 | 9.4 | 487.5 |

150 | 225 | 5.5 | 425 | 9.4 | 505 | 10.9 | 595 |

200 | 300 | 7.1 | 520 | 9.8 | 660 | 12.9 | 800 |

250 | 375 | 9.4 | 655 | 10.4 | 798 | 15.2 | 995 |

300 | 450 | 9.4 | 750 | 13.3 | 950 | 17.3 | |

350 | 525 | 9.8 | 925 | 15.8 | 1095 | 19.6 | |

400 | 600 | 10.6 | 1020 | 16.8 | 23.8 | ||

450 | 675 | 13.0 | 1155 | 18.3 | 26.2 | ||

500 | 500 | 13.7 | 1290 | 18.9 | 26.2 | ||

600 | 600 | 16.2 | 1540 | 22.7 | 27.6 | ||

700 | 700 | 18.6 | 24.5 | 37.2 | |||

800 | 800 | 18.6 | 28.3 | 43.8 | |||

900 | 900 | 20.0 | 30.2 | 48.3 | |||

1000 | 1000 | 22.9 | 33.2 | 52.6 | |||