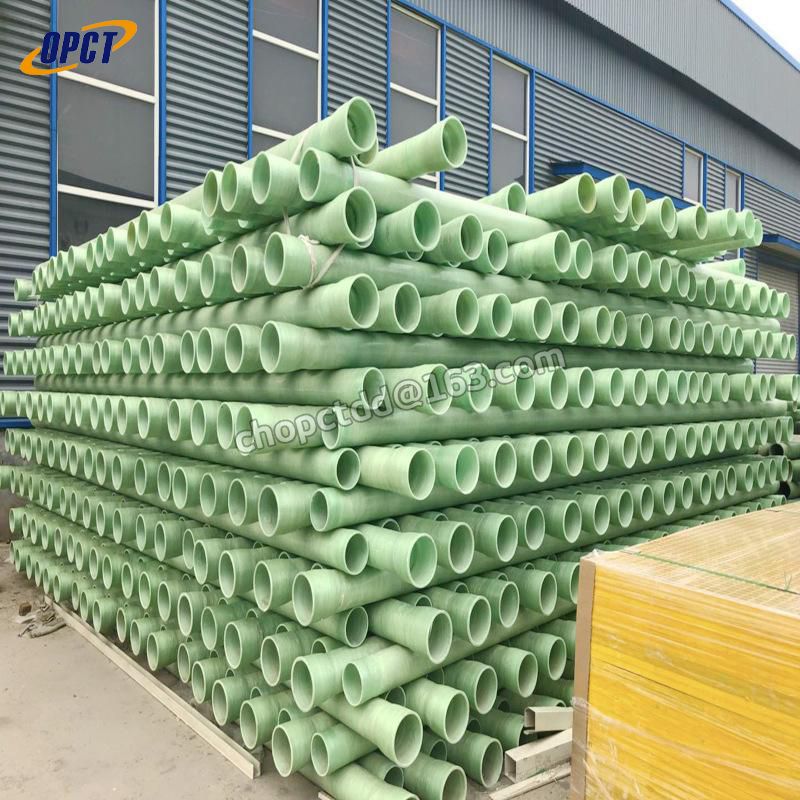

Fiberglass reinforced plastic process pipe

Fiberglass reinforced plastic process pipe

The full form of FRP is fiberglass reinforced plastic that is a composite material consisting of a polymer matrix reinforced with fibers.FRP pipe is a pipe manufactured of FRP material by filament winding method.

Fiberglass reinforced plastic process pipe is a kind of non-metallic pipe with light weight, high strength and corrosion resistance. The production is controlled by computer,according to the requirements to make pipe lining and debubbling treatment, after the inner lining is gelled, the structural layer is wound according to the designed line type and thickness, finally the outer protective layer is laid. If the user requests, can add flame retardants, UV protection agents and other special functional additives or fillers.

Fiberglass reinforced plastic pipe Characteristics:

1. The process glass fiber reinforced plastic pipe has excellent hydraulic characteristics, and the hydraulic characteristics are one of the important characteristics. Excellent hydraulic characteristics means that the fluid head loss is small, and a smaller diameter or smaller power delivery pump can be used, thereby reducing initial investment in pipeline engineering, saving power, and reducing operating costs. The inner surface of FRP is quite smooth. Generally, the surface roughness can be taken as 0.008. During operation, the inner surface of steel pipes, cast iron pipes, cement pipes, etc. often undergo local corrosion and become more and more rough, while FRP always keeps the smooth surface of the new tube.

2. The process glass fiber reinforced plastic pipe is resistant to chemical corrosion and has a long service life, and is suitable for transporting various acids, alkalis, salts and organic solvents.

3. Fiberglass reinforced plastic process pipe installation, maintenance costs are low, in general, glass fiber pipe does not need special anti-corrosion treatment; pipe is relatively light, lifting equipment tonnage is small, power consumption is less. The length of the FRP tubeis longer than that of the cement pipe and the cast iron pipe, and the joints are relatively reduced, which will reduce the installation and maintenance costs, which has been proved by many engineering practices at home and abroad.

4. The fiberglass process pipe has excellent physical properties. The specific gravity of FRP pipe is 1.8-2.1, which is about 1/4 of steel. Fiberglass reinforced plastic pipe has higher specific strength than steel, cast iron and plastic. The weight of FRP pipe is generally not larger than 1/3 that of steel pipe of the same specification, has excellent physical and mechanical properties, in addition, the expansion coefficient of fiberglass reinforced plastic pipe is roughly equivalent to steel and the heat transfer coefficient is only 0.5% of steel, which is a good thermal and electrical insulator.

5. The process glass fiber reinforced plastic pipe has great design flexibility and short modification period. The pipe wall is a layered structure, which can be changed by changing the resin system or using different reinforcement materials to adjust the physical and chemical properties of the FRP pipe to suit different media and working conditions. The short modification cycle is a distinctive feature of filament-wound composites, and isotropic metal tubing cannot be compared to it.

Product specifications | |||||

DN (mm) | 0.6MPa | 1.0MPa | 1.6MPa | 2.5MPa | L (m) |

T (mm) | T (mm) | T (mm) | T (mm) | ||

25 | 4.5 | 4.5 | 4.5 | 4.5 | 1 |

32 | 4.5 | 4.5 | 4.5 | 4.5 | 1 |

40 | 4.5 | 4.5 | 4.5 | 4.5 | 1 |

50 | 4.5 | 4.5 | 4.5 | 4.5 | 3 |

65 | 4.5 | 4.5 | 4.5 | 5.5 | 3 |

80 | 4.5 | 4.5 | 4.5 | 5.5 | 6 |

100 | 4.5 | 4.5 | 5.5 | 5.5 | 6 |

125 | 5 | 5 | 5.6 | 6.5 | 6 |

150 | 5 | 5.5 | 6 | 7.5 | 6 |

200 | 5.5 | 6 | 6.5 | 8 | 6 |

250 | 6 | 6.5 | 6.5 | 9.5 | 6 |

300 | 6.5 | 7 | 7 | 10.5 | 12 |

350 | 6.5 | 7 | 7.5 | 11.5 | 12 |

400 | 7 | 7.5 | 8 | 14 | 12 |

450 | 7 | 7.5 | 8 | 15 | 12 |

500 | 7.5 | 8 | 9 | 16 | 12 |

600 | 8.5 | 9 | 12 | 19 | 12 |

700 | 9 | 11 | 14 | 22 | 12 |

800 | 9.5 | 12.5 | 16 | 23.5 | 12 |

900 | 10.5 | 14 | 17.5 | 25 | 12 |

1000 | 12 | 15 | 19 | 27 | 12 |

1200 | 13 | 12 | |||

1400 | 16 | 12 | |||

1500 | 17 | 12 | |||

1600 | 18 | 12 | |||

1800 | 20 | 12 | |||

2000 | 23 | 12 | |||

2200 | 24 | 12 | |||

2500 | 27.5 | 12 | |||

2600 | 28.6 | 12 | |||

2800 | 30.2 | 12 | |||

3000 | 32.5 | 12 | |||

3400 | 35.9 | 12 | |||

3600 | 37.9 | 12 | |||

4000 | 39.8 | 12 | |||

Fiberglass reinforced plastic process pipe Connection method

1. Socket-spigot joint with single seal ring

2. Socket-spigot joint with double seal ring

3. Socket-spigot joint with gluing

4. Butt joint

5. Flange joint

Application

FRP/GRP process pipe mainly used in ventilation pipe system, desulfurization system, electric power system, chemical plant, metallurgical plant, pharmaceutical plant, brewing plant and other fields.