FRP GRP SMC fiberglass firefighting water tank

FRP GRP SMC fiberglass firefighting water tank

We are GRP water tank manufacturer, and the GRP water tank is also called SMC panel storage tank, FRP modular water tank. It is a new type of tank. It is made of high qualified SMC panels. Sheet molding compound (SMC) is a kind of fiberglass reinforced plastic, which is a mixture of unsaturated polyester resin with impregnating augmentation material, filling material and glass fiber. SMC water tank is nontoxic, durable, lightweight, corrosion resistant and good-looking. SMC tank panel size is 1000mm×1000mm, 1000mm×500mm, 500mm×500mm, and the tank volume is 0.125~1200CBM. We can also produce customized products according to the size specified by customers.

Meanwhile, it's easy to maintain and long-life. It is widely used in water storage in residential buildings, schools, hotel. SMC water tanks are used both for domestic water as well as medicine and health where needs good water supply quality.

Fiberglass sectional water tank performance

Tensile strength Mpa | ≥70MPa |

Bending strength | ≥100 Mpa |

Flexural Modulus of Elasticity | ≥ 5900MPa |

Barcol hardness | ≥60 |

Water absorption | ≤ 1.0% |

Glass fiber content | ≧25% |

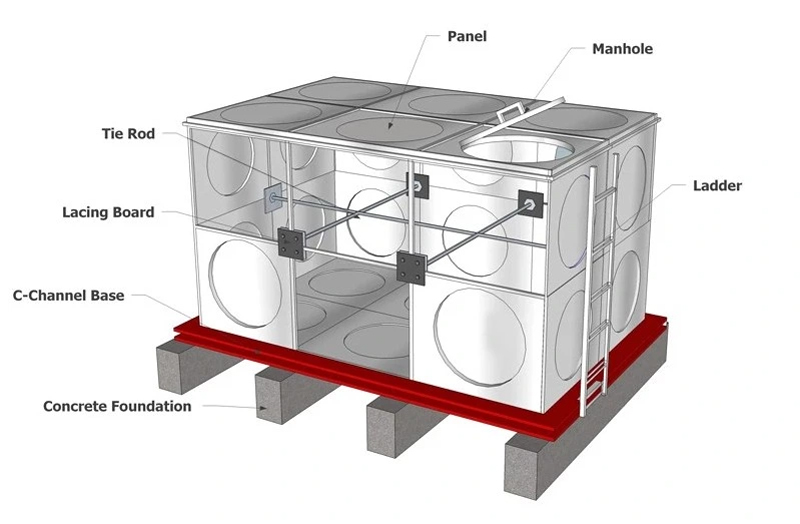

FRP/GRP combined type water tank installation instructions:

1. Based on the first plane leveling cement, on the same plane so that the error should not exceed ± 0.5cm.

Welding channel: channel according to the size of the tank welding good match its size and the tank floor size, channel steel welding complete, the diagonal measurements, error of ± 0.5cm, and all welds to connect uniform row seam line.

2. Install the end state: water tank according to the board printed number and description of the arrangement, the connection of the tank bottom, while between two boards add sealing tape, bolted. Securely sealed bottom plate, bolt afterburner afterburner to a uniform, one-time can not be too much force, otherwise due to uneven force caused by the split plate phenomenon.

3. Is connected with a fixed angle iron and channel steel base plate, so that the tank housing more firmly fixed on the basis of the channel.

4. Install states: water tank according to the board printed number and description to identify the layers BOND NO tank state body, and previously separate state body assembled with bolts.

5. Install stretch: Stretch inner tank according to the size, number and find internal reinforcement length. Measuring stretch of wire reinforcement plate fastening parts, Indian painting, drilling, on to the wire, tighten to make a flat stretch in balance with the tank housing. If there is a large error between the casing and reinforcement, can be adjusted by adjusting the size of the error bolt tightness, until the error is adjusted to a minimum so far.

6. Install the cover: the final installation of the tank top cover, and even fastening bolts can not force too large or too small.

7. Tanks fully installed, unified inspection, adjustment, test the water does not leak in compliance.